Industry Trends in Aluminum Foundry Solutions

Various factors are driving notable transformation in the aluminum foundry service industry. Advanced technologies and automation are revolutionizing manufacturing processes. At the same time, sustainability programs are gaining momentum in response to environmental challenges. However, challenges such as raw material price volatility and labor shortages continue to pose risks. Understanding these dynamics is essential. What implications do these trends hold for the future of the industry?

Advancing Automation in the Aluminum Foundry Industry

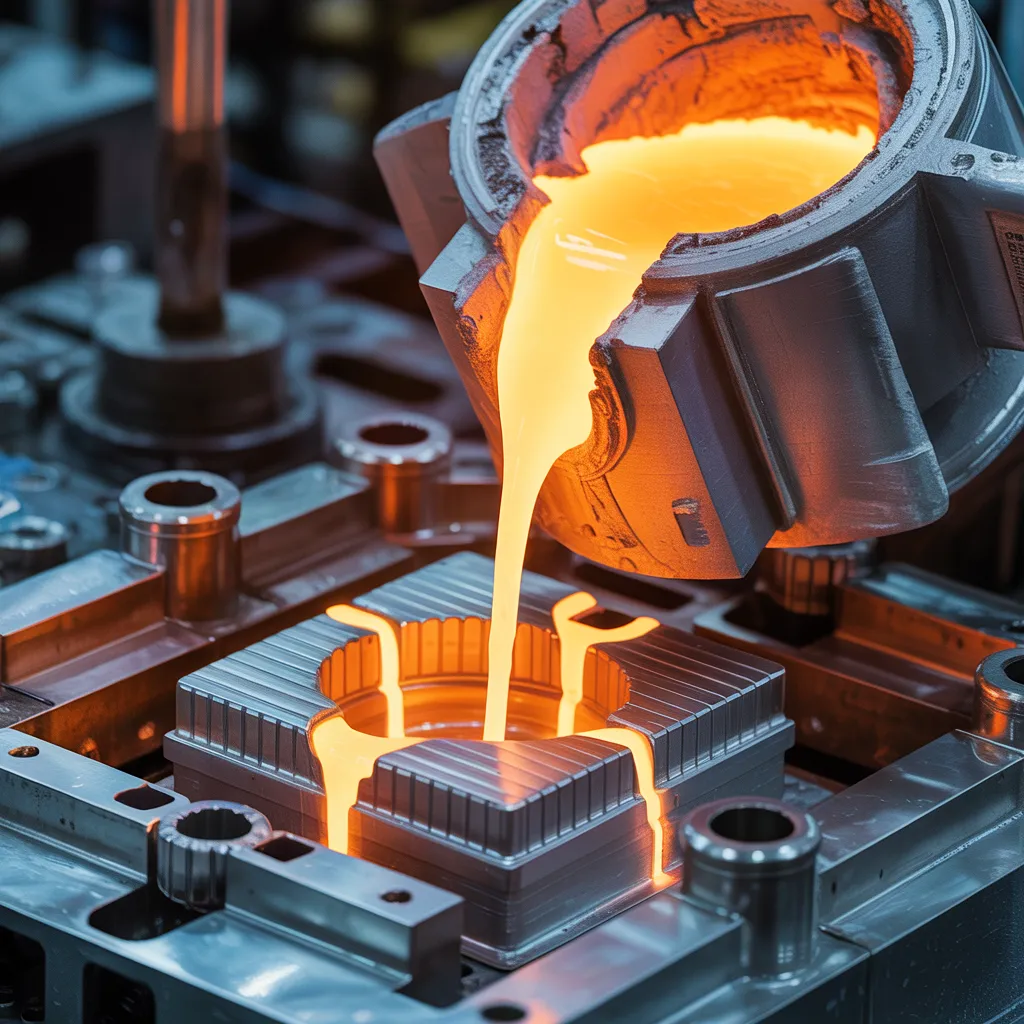

As industries strive for efficiency and precision, the rise of automation in aluminum foundry services has become increasingly evident. This shift reflects a broader trend towards integrating advanced technologies within manufacturing processes. Automated systems, such as robotics and artificial intelligence, are being deployed to enhance tasks such as molding, pouring, and casting. By reducing manual labor, these technologies not only improve safety but also minimize the potential for human error.

Furthermore, automation allows for real-time monitoring and data collection, permitting foundries to optimize performance. This technological advancement is motivated by the requirement for quicker production cycles and improved quality standards. As a result, several aluminum foundries are embracing automation to remain competitive in a fast evolving marketplace. The transition towards automated solutions indicates a commitment to innovation and adaptability, which are vital for meeting the increasing demands of different industries reliant on aluminum components.

How Automated Systems Improve Production in Aluminum Foundries

How can automation elevate production efficiency in aluminum foundries? Automated solutions enhance various workflows, notably cutting down on manual labor and human errors. Via the integration of robotic systems for processes including molding, pouring, and finishing, foundries can secure enhanced accuracy and consistency in their output. Automated technologies further support real-time tracking, facilitating prompt adjustments and decreasing downtime.

In addition, automation improves safety by decreasing worker exposure to dangerous environments. This technology facilitates a more effective use of resources, optimizing energy consumption and raw material usage. With advanced data analytics, aluminum foundries can predict equipment failures and schedule maintenance in advance, further boosting productivity.

What's Latest in 3D Printing for Aluminum Foundries?

Current breakthroughs in 3D printing technology are revolutionizing aluminum foundries, delivering innovative solutions for design and production. The integration of metal additive manufacturing allows foundries to fabricate complex geometries that were previously unattainable through traditional methods. This breakthrough allows for lightweight, high-strength components, optimizing material usage and decreasing waste.

Furthermore, the pace and flexibility of 3D printing enhance prototyping capabilities, enabling swift iterations and decreased lead times. Foundries can now rapidly adapt designs in response to real-time feedback, optimizing the development process.

Moreover, progress in 3D printing materials, including aluminum alloys expressly formulated for additive manufacturing, are enhancing the mechanical properties of printed parts. These developments are creating opportunities for aluminum foundries to discover new applications, such as aerospace, automotive, and specialized industrial components, consequently driving innovation across multiple sectors. As these technologies persistently evolve, they will redefine the landscape of aluminum foundry services.

Sustainable Practices Modernizing Aluminum Foundries

Environmentally responsible methods are progressively transforming aluminum foundries, driving the industry towards more environmentally responsible operations. Many foundries are implementing recycling initiatives, where scrap aluminum is repurposed, significantly reducing consumption of energy and waste production associated with primary aluminum production. Furthermore, advancements in energy-efficient melting technologies are being adopted, decreasing greenhouse gas emissions.

Furthermore, foundries are looking into the use of renewable energy sources, such as solar and wind power, to additionally reduce their carbon footprint. Introducing closed-loop water systems has also gained momentum, boosting water conservation while upholding operational efficiency.

Supply chain visibility is being made a priority, supporting the sourcing of materials from sustainable suppliers. These efforts not only bolster environmental stewardship but also align with the rising consumer demand for sustainable products. As aluminum foundries incorporate these practices, they are not only improving their operational sustainability but also positioning themselves as leaders in an increasingly eco-conscious market.

How Data Analytics Improves Efficiency in Aluminum Foundries

Data analytics revolutionizes efficiency in aluminum foundries by offering valuable insights that streamline operations and reduce costs. By harnessing analytics from various stages of the production process, foundries can recognize performance gaps and optimize procedures. Advanced predictive tools play a crucial part in forecasting maintenance needs, thereby reducing unexpected interruptions and prolonging machinery life.

Moreover, data analytics makes possible enhanced inventory management, helping foundries to preserve perfect stock levels of raw materials, consequently reducing waste and associated costs. Real-time monitoring of production metrics enables quick decision-making, assisting managers respond to changing conditions quickly.

Additionally, advanced data visualization tools enable teams grasp complex data sets, making it easier to detect trends and execute improvements. All in all, the integration of data analytics cultivates a culture of continuous improvement, positioning aluminum foundries to satisfy the demands of an evolving market while boosting productivity.

Specialized Alloys: Solving Issues in Today's Manufacturing

The advancement of cutting-edge alloy formulations is essential for meeting the challenges faced in current manufacturing. These advanced alloys provide enhanced mechanical properties that can improve product performance and reliability. As industries aim to enhance efficiency and decrease costs, the function of these materials becomes ever more important.

Revolutionary Alloy Combinations

As sectors more and more need materials that can withstand extreme conditions while preserving performance and cost-effectiveness, innovative alloy formulations have emerged as a critical solution. These formulations leverage advanced metallurgical principles and modern processing techniques to produce aluminum alloys designed for specific applications. By incorporating elements such as lithium, magnesium, and silicon, manufacturers are able to enhance the properties of aluminum, yielding lighter, more durable products. These alloys address challenges presented by high temperatures, corrosive environments, and mechanical stress, thereby expanding the potential for use in sectors such as aerospace, automotive, and marine. The continued development of these innovative alloys not only facilitates sustainability goals through improved resource efficiency but also enhances competitiveness in an evolving market landscape.

Advanced Physical Characteristics

As numerous sectors encounter growing requirements for materials read the information merging strength and reduced weight, sophisticated alloys have surfaced as a critical answer to improve mechanical properties. These groundbreaking materials, often engineered with particular elemental compositions, deliver superior tensile strength, fatigue resistance, and corrosion resistance. Industrial facilities are steadily adopting advanced aluminum alloys in applications ranging from aerospace to automotive, where reliability and functionality are essential. The integration of alloying elements such as lithium and magnesium has brought about significant advancements in weight reduction without sacrificing durability. Additionally, these alloys permit manufacturers to meet stringent industry standards while enhancing production processes. Therefore, the adoption of advanced alloys steadily revolutionizes the landscape of modern manufacturing, propelling efficiency and performance to remarkable levels.

Your Questions Answered

What Kinds of Aluminum Alloys Are Frequently Used in Foundry Services?

Commonly used aluminum alloys in foundry services include 356, 319, and A356, with each providing unique properties. These alloys are preferred for their outstanding casting characteristics and strength, making them ideal for various applications in manufacturing.

In What Ways Do Aluminum Foundries Achieve Quality Control Across Production?

Foundries specializing in aluminum establish quality control through stringent testing methods, including mechanical property assessments and chemical analysis. They also comply with standardized processes, conduct routine inspections, and implement advanced technologies to monitor consistency in production and product quality.

What Are the Principal Challenges Facing Aluminum Foundries Today?

Today's aluminum foundries confront difficulties like rising raw material costs, stringent environmental regulations, labor shortages, technological advancements, and competition from alternative materials, all of which impact efficiency, profitability, and total operational sustainability.

How Do Foundries Handle Aluminum Waste and Recycling?

Foundries manage waste and recycling by deploying efficient collection systems, using advanced separation technologies, and fostering the reuse of scrap aluminum. These practices help minimize environmental impact while enhancing resource recovery and operational efficiency.

How Long Are the Typical Lead Times for Aluminum Foundry Services?

Standard lead times for aluminum foundry services vary from a couple of weeks to several months, based on factors such as intricacy of the project, order volume, and the foundry's production capacity and scheduling efficiency.