Sophisticated Aluminum Foundry Services for Custom and Commercial Castings

Sophisticated aluminum foundry solutions are crucial in current manufacturing operations. They blend advanced technological solutions with conventional casting techniques to create both custom and industrial components. These services elevate design capabilities and enhance operational efficiency. As manufacturing sectors develop, the call for top-tier casting products remains on the rise. Recognizing the intricacies of these services shows their critical role in satisfying diverse industrial needs. What impact does this carry for the next generation of manufacturing?

Comprehending Advanced Aluminum Foundry Solutions

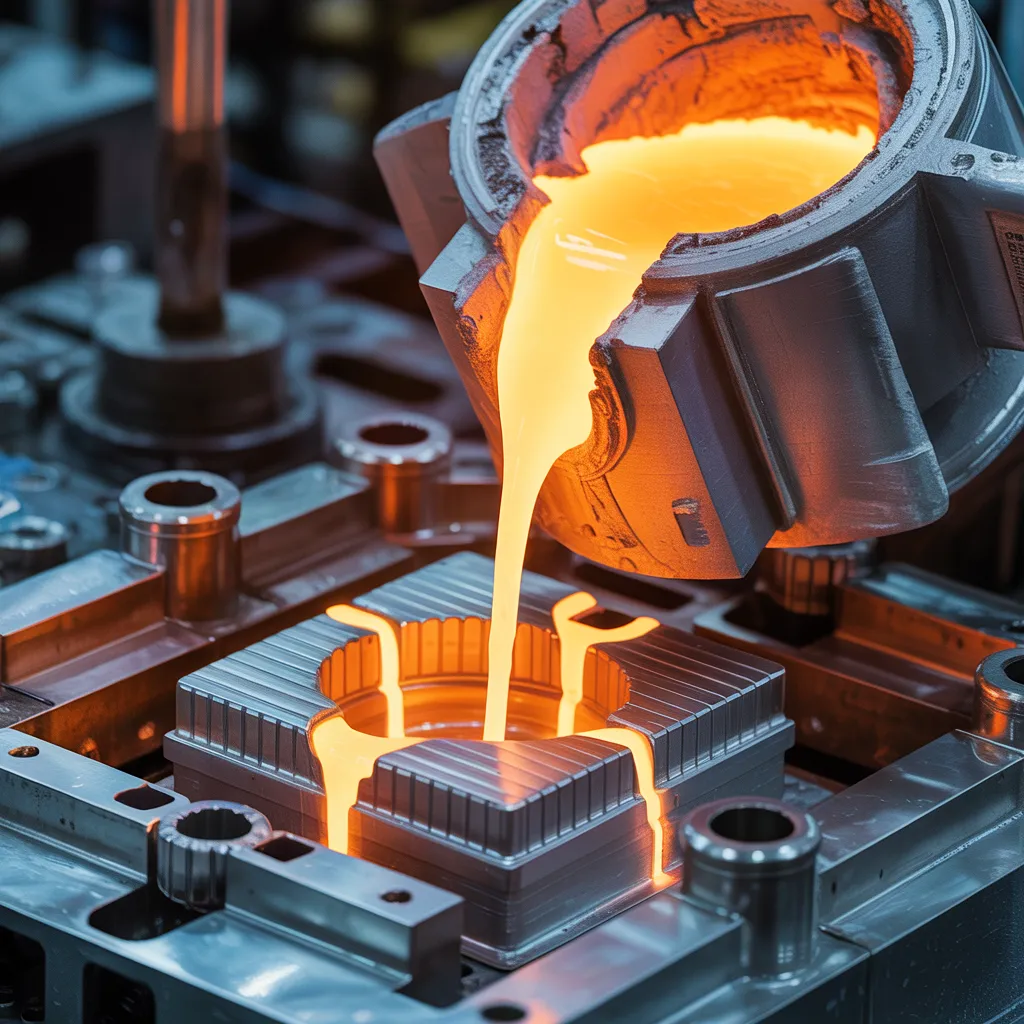

As sectors advance, mastering advanced aluminum foundry services becomes essential for manufacturers seeking efficiency and quality. These services include a range of processes like mold design, metal pouring, and thermal treatment, all intended for producing high-precision castings. Advanced aluminum foundries implement state-of-the-art technologies such as computer-aided design (CAD) and simulation software, which boost the accuracy of molds and minimize production time. Additionally, the implementation of automated systems in the casting process decreases human error and increases output consistency.

Moreover, advanced foundry services are defined by their potential to cater to diverse industrial requirements, from automotive components to aerospace parts. This flexibility allows for customized approaches, guaranteeing that manufacturers get products customized to their requirements. By adopting these modern techniques, companies can enhance their operational efficiency and maintain competitive advantages in an increasingly demanding market. Grasping these services is critical for manufacturers seeking to optimize their production capabilities.

Advantages of Aluminum for Custom Castings

Though multiple metals work well for custom castings, aluminum excels because of its distinctive mix of attributes that improve performance and efficiency. Its minimal mass properties make it well-suited for applications requiring decreased weight, including automotive and aerospace sectors. Aluminum additionally demonstrates superior resistance to corrosion, ensuring longevity and durability for cast components.

This metal's superior thermal and electrical conductivity further increases its usefulness, making it appropriate for electronic and heat exchange applications. Additionally, aluminum can be easily machined and fabricated, permitting detailed designs and stricter tolerances in custom castings.

Its recyclability is another significant advantage, advancing sustainability initiatives while maintaining material integrity. Additionally, aluminum's capability to tolerate high temperature variations without warping adds to its reliability in go now demanding environments. All things considered, the benefits of aluminum make it an ideal choice for manufacturers pursuing effective and durable custom castings.

Key Differences Between Custom and Industrial Aluminum Castings

Custom aluminum castings and industrial aluminum castings vary significantly in design flexibility and production volume. Custom castings often allow for more intricate designs, tailored to specific needs, while industrial castings prioritize efficiency and cost-effectiveness for larger quantities. Recognizing these differences is crucial for selecting the appropriate casting method based on project requirements.

Flexibility in Design and Complexity

Design adaptability and intricacy set apart custom aluminum castings from their industrial counterparts, permitting manufacturers to customize components to specific applications. Custom castings enable intricate designs, accommodating specialized shapes and features that meet precise functional requirements. This adaptability is essential in industries such as aerospace and automotive, where performance and efficiency depend on specialized components. In contrast, industrial castings typically conform to standardized designs designed for mass production. While they may offer reliability and uniformity, they lack the refined specifications often required in specialized projects. The ability to integrate complex geometries, varying wall thicknesses, and customized surface finishes in custom castings elevates overall product performance, providing a competitive advantage for businesses that focus on innovation and precision in their manufacturing processes.

Production Volume and Cost

How can production volume and cost influence the selection between custom and industrial aluminum castings? Production volume plays a vital role in determining the overall cost and feasibility of aluminum casting projects. Industrial aluminum castings are typically produced in large quantities, gaining from economies of scale that reduce the per-unit cost. In contrast, custom castings are often made in smaller batches, which can cause higher production costs due to the specialized nature of the molds and processes involved. Additionally, the complexity of custom designs may require more intricate tooling, further increasing expenses. Consequently, businesses must assess their specific needs against budget constraints and production capabilities to make informed decisions about whether to opt for custom or industrial aluminum casting solutions.

How Technology Advances Aluminum Foundry Procedures

Advanced technology fulfills an important role in enhancing aluminum foundry processes by implementing automation and innovative methods. The integration of 3D printing has modernized mold creation, while advanced quality control techniques deliver superior product consistency. Together, these advancements enhance efficiency and precision in aluminum casting operations.

Casting Process Automation

In recent years, a substantial shift towards automation has transformed aluminum casting processes, boosting precision and efficiency. Advanced technologies, such as robotic arms and automated molding systems, have streamlined operations, decreasing manual labor and minimizing human error. These innovations allow foundries to achieve consistent quality in castings while improving production times. Furthermore, automation enables real-time monitoring and data collection, allowing for immediate adjustments to maintain optimal conditions throughout the casting process. This integration of technology not only decreases waste but also supports sustainable practices within the industry. By implementing automation, aluminum foundries are well-positioned to meet the growing demands for custom and industrial castings, positioning themselves competitively in a rapidly evolving market.

Advances in 3D Printing

Additive manufacturing, commonly known as 3D printing, has emerged as a groundbreaking force in the aluminum foundry sector, revolutionizing traditional casting techniques. By facilitating the creation of complex geometries and detailed designs, this technology enables foundries to manufacture lighter, stronger components with improved efficiency. The integration of 3D printing into aluminum foundry processes supports rapid prototyping, reducing lead times substantially. Additionally, it enables the customization of parts tailored to specific industrial applications, boosting overall production flexibility. The reduction in material waste and energy consumption further underscores the environmental benefits of 3D printing. As the industry continues to embrace these innovations, aluminum foundries are positioned to strengthen their competitiveness and meet evolving market demands efficiently.

Sophisticated Quality Assurance Techniques

The incorporation of innovative manufacturing processes, such as 3D printing, has facilitated enhanced quality control techniques in aluminum foundries. These innovations enable accurate monitoring of casting parameters during production, leading to enhanced consistency and reduced defects. Automation systems leveraging artificial intelligence can evaluate data in real-time, recognizing anomalies that may impact quality. Moreover, non-destructive testing methods, including ultrasonic and X-ray inspections, guarantee that internal structures comply with stringent specifications without damaging the final product. Implementing these technologies not only optimizes the production process but also promotes a culture of continuous improvement, enabling foundries to adapt quickly to evolving industry standards. As a result, these advanced quality control techniques produce superior outcomes in custom and industrial aluminum castings.

How Aluminum Casting Services Minimize Production Costs

Manufacturers experience considerable cost reductions through aluminum foundry services that streamline production processes. Labor costs are minimized and material waste is reduced through the utilization of advanced casting techniques and automation. The precision offered by modern foundry technologies guarantees that components are produced with fewer defects, decreasing the need for expensive rework and scrap. Moreover, the ability to produce complex geometries in a single casting reduces assembly time and costs associated with multiple parts.

Furthermore, aluminum's lightweight properties lead to lower shipping costs and better energy efficiency during use, which can lead to long-term savings. Foundries typically provide customized solutions that align with specific project requirements, optimizing both production timelines and resource allocation. Overall, integrating aluminum foundry services into manufacturing operations not only boosts operational efficiency but also greatly decreases overall production expenses, positioning companies for greater competitiveness in their respective markets.

Ensuring Superior Standards in Foundry Services for Aluminum

Quality control in aluminum foundry services is crucial for maintaining the advantages obtained from cost reduction strategies. Robust quality control measures ensure that castings fulfill rigorous specifications and performance standards, thereby enhancing customer satisfaction and trust. This process involves meticulous inspection techniques, including visual assessments, dimensional checks, and mechanical testing.

Modern foundries commonly use non-destructive testing procedures to detect potential defects without compromising the integrity of the castings. Additionally, employing standardized protocols helps in maintaining consistency throughout the production cycle.

Choosing suppliers serves a crucial function in maintaining quality, as reputable suppliers provide high-grade raw materials that influence the final product's reliability and durability. Continuous training of personnel in quality management practices fosters a culture of excellence within the foundry. Finally, a unwavering dedication to quality not only upholds the integrity of aluminum castings but also situates the foundry as a leading force in the industry.

Future Trends in Aluminum Foundry Services and Manufacturing

Modern technology is revolutionizing the landscape of aluminum foundry services and manufacturing, paving the way for enhanced efficiency and sustainability. Progress in automation and robotics are streamlining production processes, reducing labor costs, and decreasing human error. Additionally, the integration of artificial intelligence and machine learning is allowing for predictive maintenance and quality control, maintaining peak performance and decreasing downtime.

Additionally, the industry's focus on eco-friendly practices is driving the implementation of recycled aluminum, which not only lowers energy consumption but also addresses environmental concerns. The development of advanced casting technologies, such as 3D printing, is further transforming production potential, enabling the creation of complex designs and minimized material waste.

With the growing demand for lightweight and high-strength materials across multiple industries, aluminum foundry services are set to evolve, offering tailored solutions that satisfy the unique requirements of diverse applications, from automotive to aerospace. These trends are laying the foundation for a more environmentally friendly and efficient future in aluminum manufacturing.

Popular Questions

What Is the Normal Lead Time for Custom Aluminum Castings?

The normal lead time for custom aluminum castings extends from four to twelve weeks. Aspects determining this duration include intricacy, design specifications, and production capacity, which may fluctuate across different foundries and projects.

What Method Should I Use to Select the Right Aluminum Alloy for My Project?

To pick the right aluminum alloy, one should consider factors such as strength, corrosion resistance, thermal conductivity, and the specific application requirements. Working with experts can further ensure perfect selection for project needs.

Can Aluminum Castings Be Repaired or Modified After Production?

Certainly, aluminum castings can be modified or repaired post-production. Approaches such as welding, brazing, or using epoxy adhesives facilitate adjustments, though the feasibility is determined by the level of damage and the specific alloy properties involved.

What Industries Commonly Utilize Advanced Aluminum Foundry Services?

Several industries typically employ advanced aluminum foundry services, including automobile, aerospace, electronics, marine, and construction. Each sector benefits from aluminum's low weight characteristics, durability, and corrosion resistance, making it a preferred material for numerous applications.

Do Environmental Considerations Exist in Aluminum Casting Processes?

Certainly, environmental considerations in aluminum casting processes include energy consumption, greenhouse gas emissions, and waste management. Businesses are continuously embracing environmentally responsible approaches to decrease environmental impact and enhance recycling efforts within the aluminum production lifecycle.